The Bühler Holding AG is a Swiss multinational plant equipment manufacturer based in Uzwil, Switzerland.It is known for plant and equipment and related services for processing foods and manufacturing advanced materials. The organization holds leading market positions worldwide in the fields of technology as well as processes for transforming grain into flour and animal feeds, producing pasta and chocolate, and manufacturing die cast components

Buhler ranks among the international top plant constructors for more than 130 years focused on food, non-food and die-casting sectors. It is represented in more than 100 countries throu hout the world. This proximity to the customer ensures a perfect service. Buhler is famous for its long lasting and continuously developing relationship with the customers.

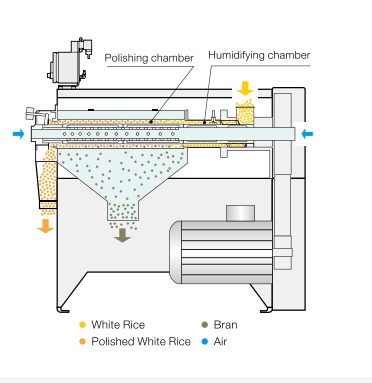

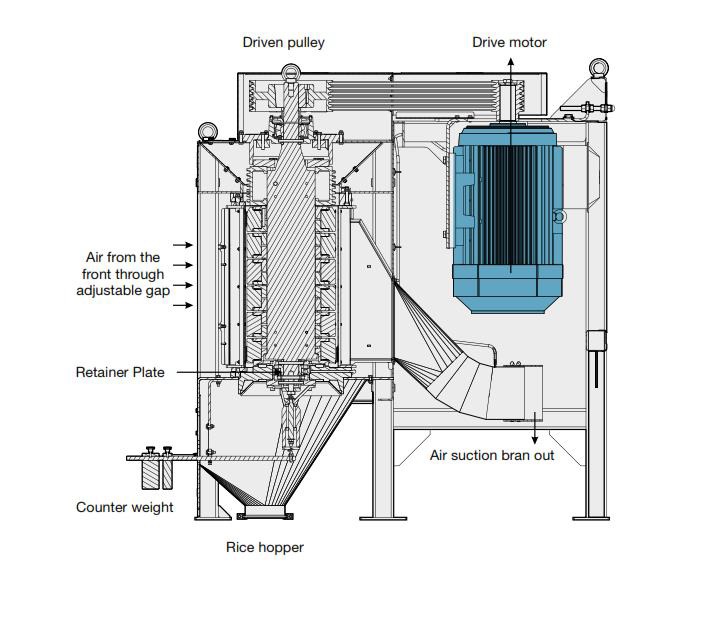

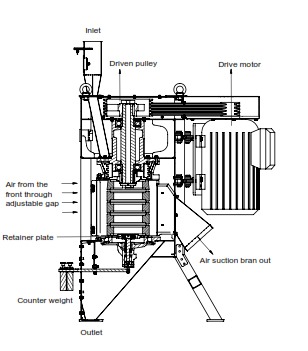

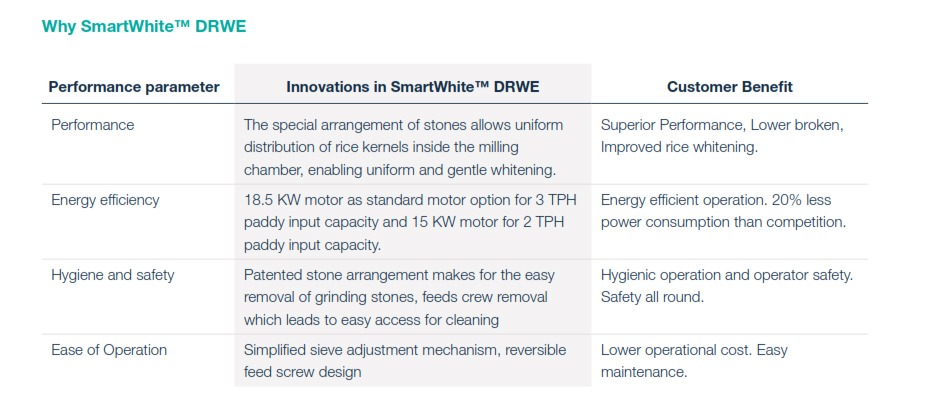

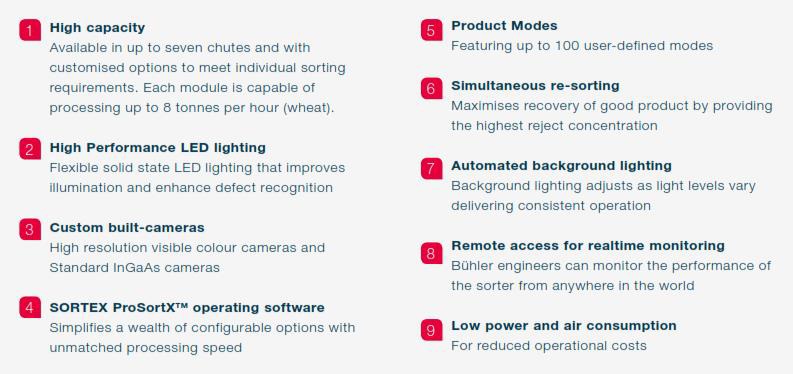

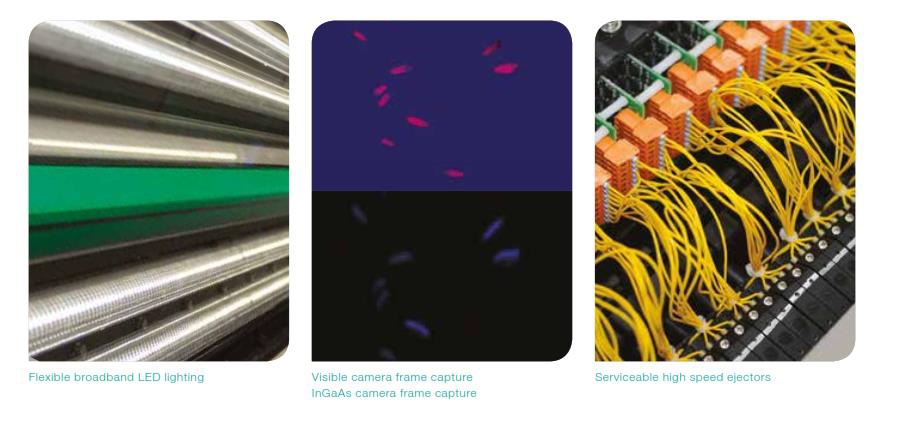

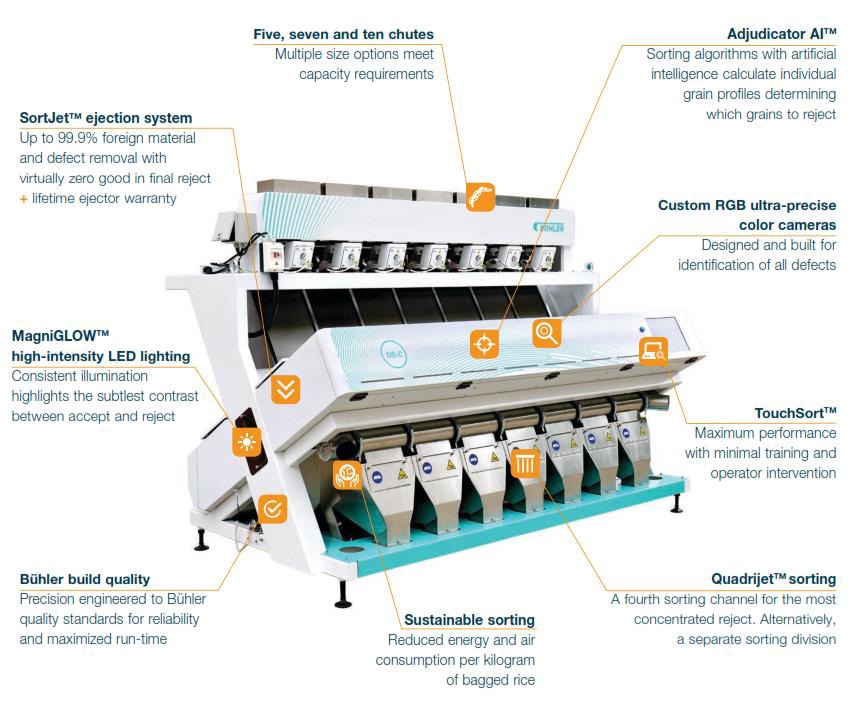

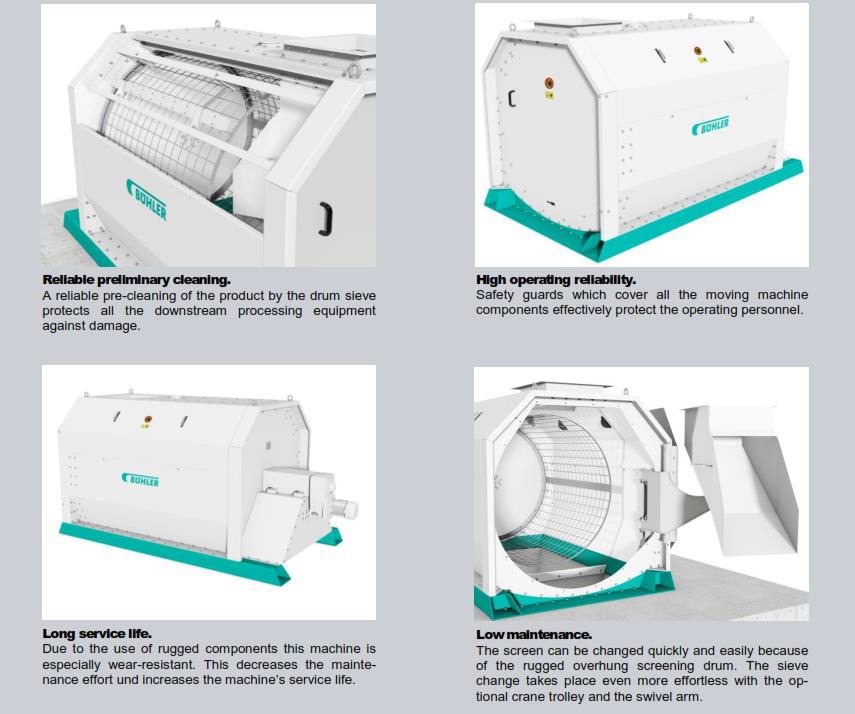

All machines are extremely sturdy and of a proven design. This ensures years of trouble free operation and the saving in down time is reflected as profits for the customer.

Further, the customer also benefits from the ongoing research and development process at Buhler, during the entire lifetime of his plant.